Seemingly, we’re all on the go. People constantly find ways to do more with the same amount of time. Some people join a teleconference while responding to emails, some shave their face while driving in traffic. and some even chew gum and walk at the same time. Perhaps the last example was exaggerated, but nonetheless, you get the point.

Could you apply this idea to project delivery in the pharmaceutical industry? Let's consider it. What if you could construct your facility and process system simultaneously? What if you could move a completed, tested and verified process system into your facility that shaved a month off of your schedule? With recent advancements, you may now have the opportunity.

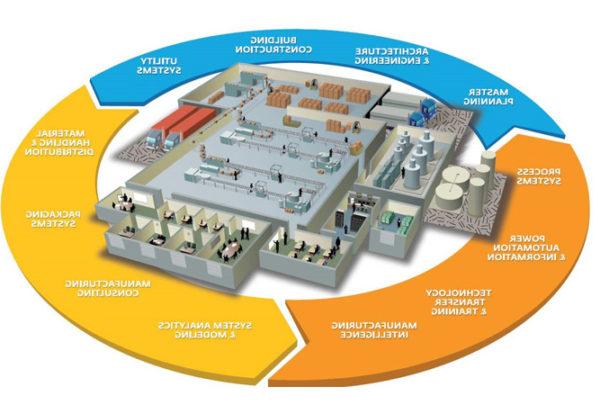

To accommodate new classes of drugs, varying market conditions and new manufacturing technologies, pharmaceutical manufacturing must continually evolve. One of the products of this evolution is the use of modular mobile clean rooms.

Ultimately, these modules, which are self-functioning processing clean rooms developed off site, help maximize the speed of project delivery and minimize facility downtime. In this blog, modular mobile clean rooms will be examined for their benefits, drawbacks and usefulness for your upcoming project.

What is a modular mobile clean room?

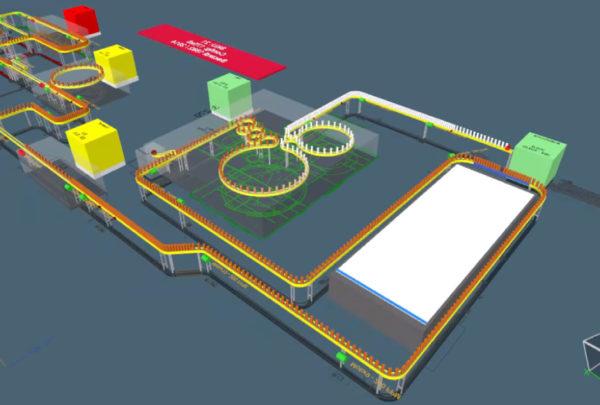

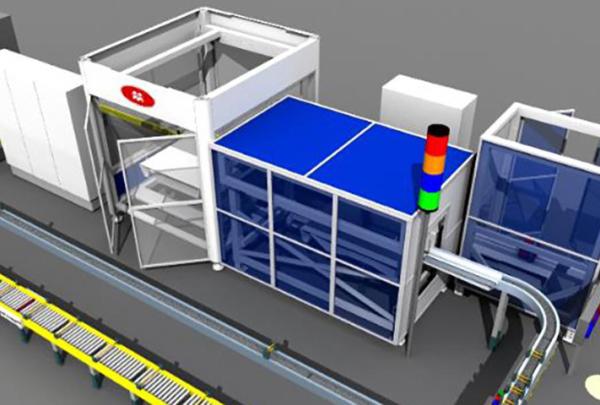

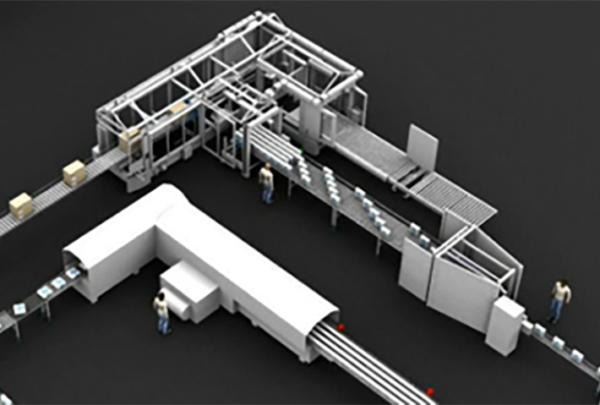

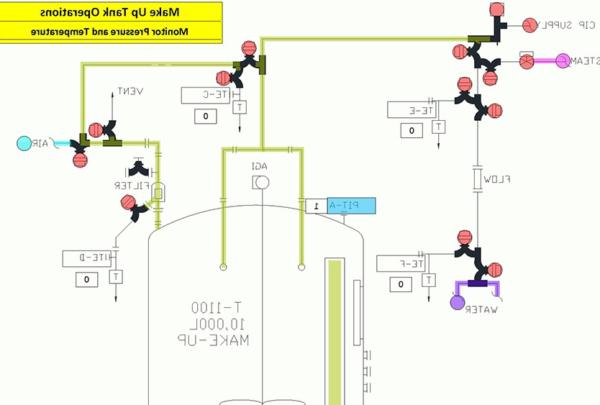

Ideally suited for small-scale portable or disposable processing equipment, a modular mobile clean room is approximately a 42’ x 18’ x 13’ unit to accommodate over the road transport consisting of a clean room which has a small mechanical room for utilities and electronics. It also includes HVAC, fire suppression, and utility distribution systems, which are connected to the main facility systems. Depending on the requirements, an HMI (Human Machine Interface, i.e. control screen), data management system, or other controls can be added as well.

These modules are built off-site in a controlled environment and are often constructed at the same time as the facility. Before shipment of the module, environmental monitoring and other validation activities can be completed while the facility is still under construction to increase speed to market.

Fast Response to Market Needs

If your company’s goal is to increase flexibility, these modular clean rooms may be a good fit. One of the major advantages of these rooms is the flexibility of the modular design. It allows for facility scale-up and scale-down without the need to shut-down or otherwise disrupt other ongoing operations. For example, if your product experiences high demand, these modules allow rapid changes in capacity that minimize the impact on your overall project timeline.

Module Size Limitations

The primary drawback of the modular mobile clean rooms is the size limitation to house tanks or other major pieces of equipment within one module. The largest tank size is about 2000 liters (L), which is generally sufficient for small scale pharmaceutical processes, but does not accommodate larger processes, such as large bioreactors or pool tanks. Although more modules with duplicate tanks and/or processes can be added, processing efficiency may be sacrificed.

Associated Costs of Mobile Clean Rooms

If you do not foresee a change in capacity or a reconfiguration of your plant, the savings associated with the construction of the modular clean rooms may not be sufficient to offset the additional costs needed to build modules. Not to mention, you also have to consider the schedule implications of shipping equipment to the module vendor earlier than a traditional build and then to your facility.

However, if you are planning to change capacity or reconfigure your plant depending on the market conditions, flexible modular facilities can provide significant cost savings. For example, consider the cost associated with downtimes and shutdowns constructing around existing operations that can be avoided by developing, testing and verifying your process system off site.

While not applicable to all situations, the concept of modular mobile clean rooms is a design philosophy we expect to see increasingly in the future. Overall, we find that pharmaceutical manufacturers are continually seeking quality facilities delivered in shorter timelines to quickly respond to market conditions. If you would like to learn how you can construct your next facility and processing facility simultaneously, please feel free to contact us to start the discussion.